System types:

Both indirect and direct measuring systems are available. Direct measuring systems have wheel sensors for measuring tire pressure and temperature, either inside the tire at the valve or rim, or, like TireMoni, outside the valve instead of the valve cap.

Indirect measuring systems They work by differentiating wheel speeds. They measure the wheel speed and infer tire pressure from the changing tire radius. They do not measure tire temperature.

Problems:

a) No pressure display, as it cannot be measured. Therefore, any savings (fuel consumption, tire mileage) cannot be achieved.

b) Systemic blind spots with simultaneous pressure loss on two or more wheels; this case is statistically unlikely but relevant for the safety function.

c) Warning thresholds are between 15 and 20% pressure loss; this is too high for practical purposes, ie the systems tend to warn too late.

d) There's no tire pressure monitoring system here, as tire pressure isn't measured. Rather, these are "flat tire warning systems," meaning, at best, the user receives a warning in the event of a pressure loss, usually without specifying the affected wheel position.

e) not suitable as a retrofit system.

Advantages: cost-effective.

Direct measuring systems with internal sensors:

Problems:

a) For installation, the tires must be removed and remounted.

b) The sensor batteries are encapsulated in the sensors and are therefore not replaceable, meaning that at the end of the battery life the sensors must be completely replaced – effort: expensive sensors and assembly effort

c) A vehicle requires two sets of sensors, one for summer and one for winter tires. This incurs costs.

d) Sensors can be mechanically damaged when the tire is removed (tire change).

e) depending on the system type, additional effort and costs for automatic wheel position assignment/detection.

f) Tires must be balanced with sensors fitted.

g) expensive in acquisition and follow-up costs

Advantages:

a) Anti-theft protection is not required as the sensors are located in the tire.

b) Measured temperature usually correlates well with tire pressure

c) high measuring accuracy (typically better than 0.1 bar)

d) practical warning thresholds of 0.2 bar (usually predefined or input of the cold filling pressure/target pressure)

e) no blind spots, as each tire has a separate measuring device

f) suitable in principle for retrofitting.

Direct measuring systems with external sensors (valve cap design):

Problems:

a) Sensors can be targeted for theft or vandalism. This can be prevented by installing the included anti-theft device, but this will make refilling the air more difficult.

b) If the installation instructions are not followed (valves that are too long), the sensors may be damaged if they come into contact with the curb.

c) Tires must be balanced with sensors installed.

d) measured temperature often does not correlate with tire pressure

Advantages:

a) Only one set of sensors for summer and winter tires

b) Batteries can usually be replaced

c) Simple wheel position assignment via sensor numbering

d) only minimal assembly effort

e) cost-effective in acquisition and maintenance/follow-up costs

f) high measuring accuracy (typically better than 0.1 bar)

g) Practical warning thresholds of 0.2 bar (usually adjustable by the user)

h) no blind spots

i) can be easily retrofitted.

TireMoni offers these systems and, like the ADAC, recommends short metal valves.

*

Pressure displays:

Warning/Warning symbol only:

Problems:

a) User has no information about the tire pressure

b) Depending on the system, the user is lulled into a (possibly false) sense of security (see blind spots above)

Advantage:

a) no unnecessary distractions

Display of only one pressure value with indication of the wheel position:

Problems:

a) Distraction, since the display must be manipulated with an operator key to query the values.

b) If pressure is lost in more than one tire, only one pressure value can be displayed.

Advantages:

a) The user is shown the pressure values on request and can thus achieve savings

b) In case of warning, the user is shown the wheel position and the pressure value.

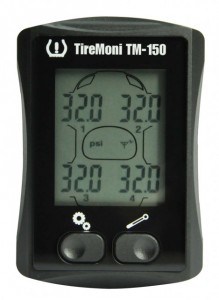

Display all pressure values simultaneously:

Problems:

Advantages:

a) Complete information about the condition of the tire pressures at a glance

b) Changes are immediately visible

c) The system function and usually also the battery status can be seen at a glance; a sensor failure would be detected immediately.

d) Acoustic and visual warning with indication of pressure values.

When considering failure probabilities, it makes sense to consider detectability and response options. A system should detect a failure, or at least make it detectable for the user, so that the user does not rely on a system that no longer functions. Furthermore, failures in the broadest sense should also include false warnings; here, too, detectability by the user is advantageous.

Example: When sunlight hits one side (e.g., the left), the tire pressure in the left tire can easily be 0.2–0.3 bar higher than in the right tire. If all four pressure values are displayed simultaneously, the user can easily recognize this and classify it as unproblematic; an automatic system may have difficulties in this case.

TireMoni shows all pressure values simultaneously and recommends short metal valves, like the ADAC.